Macchine di taglio a laser a vetro di ultima generazione per ottimale performance di taglio fino a chippatura ≤ 5 μm

-

precisione di taglio± 0,01 mm

-

Bore minimo di taglio≤ 5 μm

-

Bore minimo di taglio≤ 5um

-

Caratteristiche di sicurezzaInclude pulsante di emergenza, copertura protettiva, finestre di sicurezza laser e spegnimento autom

-

Formati di immagine e testo supportatiAI PLT DXF BMP Dst DWg LAS DXP

-

Larghezza dell'impulso< 10ps

-

Voltaggio, Powe.< 8 kW, AC220V

-

Spessore di taglioVetro ultra trasparente a taglio singolo ≤ 19 mm, vetro blu a taglio doppio ≤ 19 mm

-

ProdottoTagliatrice del laser di vetro

-

Materiale applicabileAcrilico, vetro, carta, plastica, cristallo

-

Ambiente operativoCirca 26 gradi.

-

Potenza50W/80W

-

Potenza del laser60W/80W

-

Qualità del raggioM^2 < 1.2

-

Peso della macchina2000 kg

-

Precisione di taglioAlta precisione

-

tipo di prodottoMacchina di taglio del vetro

-

Velocità0-500mm/s

-

dimensione della macchina1700 mm*1700 mm*1960 mm

-

Sistema di trasmissioneRack e Pinion

-

Area di lavoro1500 mm x 3000 mm

-

Sistema di guidaHTI

-

Marca della sorgente laserRAYCUS

-

Sistema di raffreddamentoraffreddamento ad acqua

-

Dimensione di taglio40*50cm*2

-

Ambiente di lavoro<25℃

-

lunghezza d'onda del laser1064 nm

-

Accelerazione1 g

-

Velocità tagliata0-500mm/s

-

Punti chiave di venditaAutomazione

-

Fornitore di energia220v/50hz

-

Copertura della lunghezza d'onda1064 nm

-

Vantaggipiccole lacerazioni

-

Metodo di taglioTaglio laser

-

Dimensione del lavoro600*700mm*2

-

Luogo di origineCINESE

-

MarcaCKD

-

CertificazioneISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PrezzoNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Macchine di taglio a laser a vetro di ultima generazione per ottimale performance di taglio fino a chippatura ≤ 5 μm

Descrizione del prodotto:

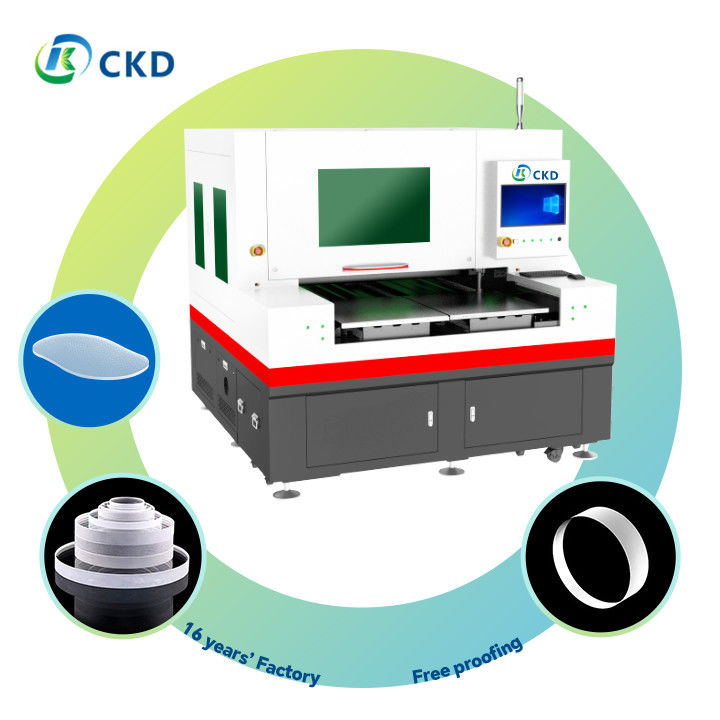

La macchina per il taglio e la spaccatura del vetro (All-in-One) è un prodotto di prima linea progettato per soddisfare tutte le vostre esigenze di taglio del vetro.Questa macchina avanzata opera con eccezionale precisione ed efficienza, che lo rende la scelta perfetta per varie applicazioni, tra cui il taglio del vetro colorato, il taglio laser a fibra e il taglio laser del vetro per la protezione ambientale.

Una delle caratteristiche principali di questa macchina è la sua efficienza energetica: con una potenza di standby di circa 500 W e un consumo medio di energia di 2,5 kW durante le operazioni di taglio, la macchina è in grado di ridurre il consumo di energia in modo significativo.Questa macchina non è solo potente, ma anche rispettosa dell'ambienteÈ dotato di modalità ecologiche che contribuiscono a ridurre il consumo di energia senza compromettere le prestazioni.

Quando si tratta di livelli di rumore, la macchina per tagliare e spaccare il vetro è progettata per funzionare silenziosamente.Questa macchina è adatta per ambienti in cui i bassi livelli di rumore sono crucialiChe si lavori in studio, in officina o in qualsiasi altro ambiente, si può contare su questa macchina per realizzare tagli precisi senza causare disturbi.

Dotata di una frequenza di impulsi che va da 1 Hz a 1000 kHz, questa macchina offre capacità di taglio versatili per soddisfare varie esigenze.Se hai bisogno di fare tagli complessi o tagli ad alta velocitàIl controllo della frequenza di impulso consente di regolare la velocità di taglio in base alle esigenze specifiche del progetto.

Un'altra caratteristica di questa macchina è la sua lunghezza d'onda di 1064 nm. Questa lunghezza d'onda ottimale garantisce risultati di taglio efficienti ed efficaci,rendendolo ideale per una vasta gamma di applicazioni di taglio del vetroSia che si lavori su materiali di vetro sottili o spessi, questa macchina offre prestazioni costanti e tagli precisi ogni volta.

Caratteristiche:

- Nome del prodotto: Macchina di taglio del vetro a laser

- Nome: macchina per il taglio e la scissione del vetro (all-in-one)

- Fonte laser di scissione: RFC02 (Radio Frequency CO2) - RFC02 10.6μm 150W (opzioni: 250W/350W) - 150W(250W/350W) raffreddamento ad acqua 1-100kHz

- Industria applicabile:

- L'industria del vetro: vetro ottico, vetro K9 e vetro ultra-sottile

- Industria degli articoli per la casa: vetro ad alto borosilicato, vetro al quarzo, vetro per articoli igienici

- Industria dei veicoli: vetro per autoveicoli, parabrezza per auto, ecc.

- Nuova energia: vetro fotovoltaico

- Apparecchi domestici: vetro per elettrodomestici, vetro per illuminazione dei pannelli

- Immobili: decorazioni architettoniche, vetri per bagni, ecc.

- Tipo di laser: picosecondo a infrarossi

- Accelerazione: 1G

Applicazioni:

Occasioni e scenari di applicazione del prodotto per la macchina di taglio del vetro laser CKD:

La macchina di taglio del vetro laser CKD è uno strumento versatile ed efficiente che può essere utilizzato in vari scenari e occasioni.

- Taglio di vetro irregolare: la macchina di taglio laser CKD è ideale per tagliare con precisione e precisione forme e disegni irregolari sul vetro.questa macchina può gestire il compito in modo efficace.

- Macchina di taglio laser a fibra: la macchina di taglio laser a vetro CKD utilizza una tecnologia laser a fibra avanzata per fornire risultati di taglio veloci e precisi.È adatto per tagliare una vasta gamma di materiali in vetro con facilità.

- Macchina di taglio vetro colorato: con le sue capacità di taglio ad alta precisione, la macchina di taglio vetro laser CKD è perfetta per tagliare pezzi di vetro colorato per scopi artistici e decorativi.Garantisce tagli puliti e lisci, preservando l'integrità del vetro.

Specificità:

- Marchio: CKD

- Numero di modello: CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE e altri

- Luogo di origine: Cina

- Certificazione: ISO, CE

- Quantità minima d'ordine: 1

- Prezzo: negoziato

- Imballaggio: imballaggio a vuoto in legno

- Tempo di consegna: 25-45 giorni

- Termini di pagamento: L/C, T/T

- Capacità di approvvigionamento: 60 serie al mese

- Accelerazione: 1G

- Motore di trasmissione: motore lineare XY + scala di griglia ottica

- Larghezza di taglio: 0,03-25 mm

- tensione, potenza: < 8 kW, AC220V

Personalizzazione:

Servizi di personalizzazione dei prodotti:

Marchio: CKD

Numero di modello: CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE,CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, CKD-SP6070C-80E

Luogo di origine: Cina

Certificazione: ISO CE

Quantità minima d'ordine: 1

Prezzo: negoziato

Imballaggio: imballaggio a vuoto in legno

Tempo di consegna: 25-45 giorni

Termini di pagamento: L/C, T/T

Capacità di approvvigionamento: 60 serie al mese

Tipo di laser: picosecondo a infrarossi

Frequenza d'impulso: 1-100 kHz

Caratteristiche di sicurezza: include pulsante di arresto di emergenza, copertura protettiva, finestre di sicurezza laser e spegnimento automatico quando la copertura è aperta per un funzionamento sicuro.

Nome: macchina per il taglio e la scissione del vetro (all-in-one)

Metodo di raffreddamento della sorgente laser a scissione: raffreddamento ad acqua

Parole chiave: Taglio di vetro irregolare, Taglio vetro a tavolo singolo, Taglio vetro colorato

Supporto e servizi:

Il supporto tecnico del prodotto e i servizi per la macchina di taglio del vetro a laser comprendono:

- Guida all'installazione iniziale e assistenza all'installazione

- sessioni di formazione per l'efficace utilizzo della macchina

- Supporto per la risoluzione dei problemi tecnici

- raccomandazioni di manutenzione regolari per garantire prestazioni ottimali

- Aggiornamenti e aggiornamenti del software per migliorare le funzionalità

Imballaggio e trasporto:

Imballaggio del prodotto:

La macchina di taglio laser del vetro è accuratamente confezionata in una robusta cassa di legno per garantire la sua sicurezza durante il trasporto.La macchina è saldamente fissata all'interno della cassa con imbottitura di schiuma e materiali di protezione aggiuntivi per evitare danniL'imballaggio è progettato per resistere a manipolazioni difficili e trasporto a lunga distanza.

Spedizione:

Una volta confezionata la macchina laser per il taglio del vetro, verrà spedita da una società logistica di buona reputazione con esperienza nella manipolazione di macchinari delicati.Il processo di spedizione sarà monitorato per garantire che la macchina raggiunga la sua destinazione in modo sicuro e in tempoAi clienti verrà fornito un numero di tracciamento per monitorare lo stato della loro spedizione.